Everything You’ll Need

| Tool/Material | Laminate Flooring | Purpose |

|---|---|---|

| Utility Knife | ✔ | Cut underlayment and edges |

| Tape Measure | ✔ | Measure room and plank cuts |

| Straight Edge | ✔ | Make straight cuts and align |

| Pry Bar | ✔ | Remove baseboards or old flooring |

| Spacers | ✔ | Keep gaps along walls |

| Tapping Block | ✔ | Tap planks gently together |

| Non-Marring Hammer | ✔ | Use with tapping block for tight fit |

| Laminate Cutter or Saw | ✔ | Cut planks to size |

| Knee Pads | ✔ | Protect knees during work |

| Level | ✔ | Make sure floor and first row are even |

| Chalk Line | ✔ | Mark straight lines |

| Underlayment Roll | ✔ (if needed) | Add cushion and soundproof |

| Jigsaw or Oscillating Tool | ✔ | Cut shapes around pipes, doors |

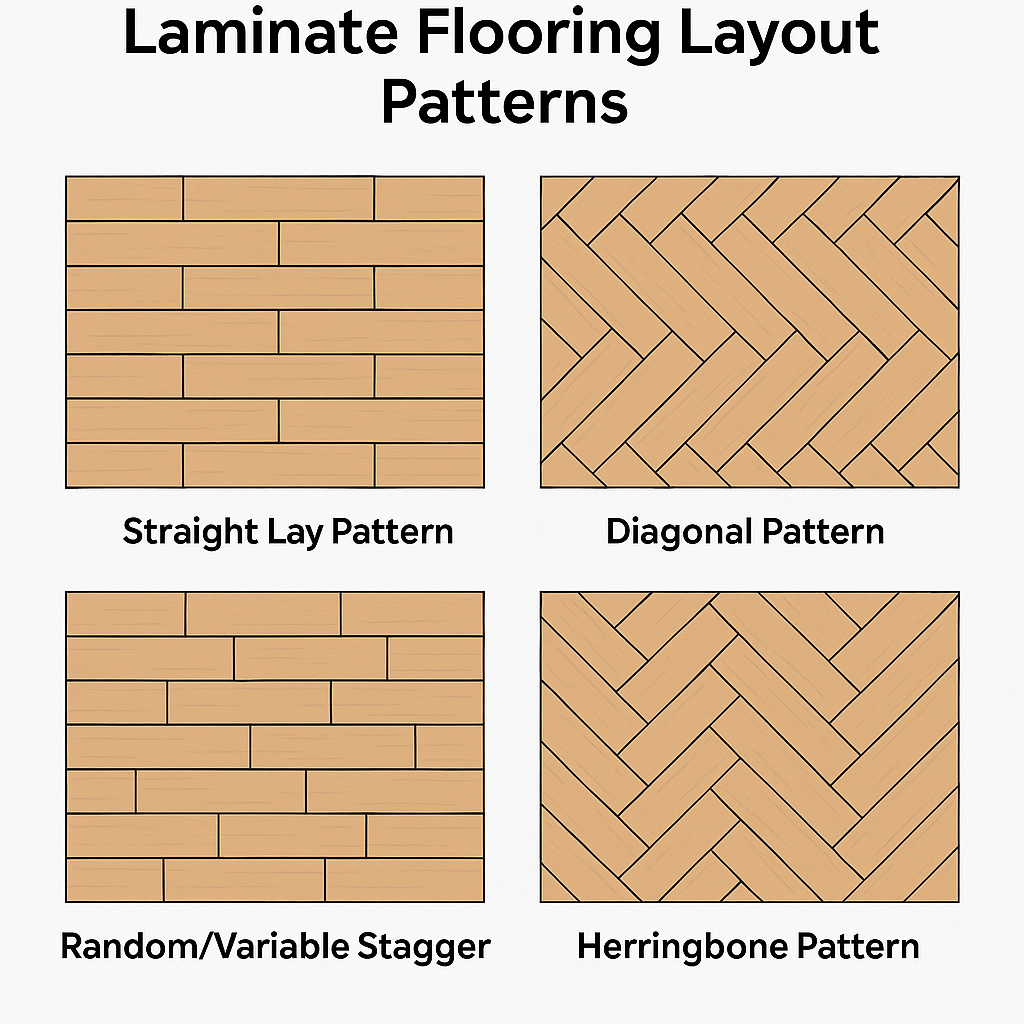

Step 1: Choose a Layout Pattern

Before you put in your laminate flooring, decide how to arrange the planks. Laminate may not have as many pattern choices as vinyl or tile, but your layout can still change how the room looks and feels.

Here are common and effective patterns for laminate flooring:

Straight Lay Pattern (Most Common)

This is the most popular and easiest option.

Planks are laid parallel to the longest wall or where the light comes in. It gives a clean, timeless look and suits most rooms.

Diagonal Pattern

Gives a more dynamic, high-end look.

Planks are placed at a 45-degree angle, making small rooms seem bigger or adding interest to square spaces. This method might need more cutting and extra material.

Random/Variable Stagger

Planks are laid in a staggered way, changing lengths row by row.

This method mimics the natural look of hardwood and avoids repetitive patterns or aligned seams.

Herringbone or Chevron (Advanced/Pro)

Some special laminate floors are made for herringbone or chevron patterns.

These styles are stunning but need precise cuts and more planning. Not all laminate brands have planks for these patterns.

Step 2: Prepare the Space

Take Off Baseboards and Old Floors

Begin by taking away any baseboards and the current flooring to have a clear surface.

Use a pry bar to gently remove the baseboards — go slowly to keep the walls safe so you can use the trim again.

If you’re taking out carpet, cut it into small parts with a utility knife and lift it up.

For tile, vinyl, or wood, use the right way to take each type off.

Clean and Check the Subfloor

Sweep and vacuum well to get rid of dust and dirt.

Look for cracks, dips, or bumps. Use a leveling compound to fill low spots and sand any bumps. A smooth subfloor is key for a lasting laminate floor.

Put Down Underlayment

Most laminate floors need underlayment unless it’s built-in.

Underlayment gives cushioning, lessens noise, and fixes small subfloor flaws.

Roll it out over the subfloor, ensuring edges touch but don’t overlap. Tape seams tightly.

✅ Pro Tip: If laying over concrete, think about adding a moisture barrier beneath the underlayment.

Step 3: Choose an Installation Method

Laminate flooring is simple for DIY projects and mainly uses one easy installation method: Click-Lock (Floating Floor). Unlike some other floors, laminate does not usually need glue or peel-and-stick ways.

Click-Lock (Floating Installation)

The Click-Lock system — also called tongue-and-groove or interlocking — is the most popular and easy option for laminate flooring. The planks click together, making a strong hold without nails or glue.

This lets the floor “float” over the subfloor, allowing it to adjust naturally with temperature and humidity changes.

Key Advantages:

No adhesives required — easier cleanup and fewer materials.

DIY-friendly — great for beginners.

Versatile — works well over different types of subfloors, including concrete and plywood.

Installation Tips:

Always leave a 1/4-inch expansion gap around the room’s edge using spacers. This stops buckling as the floor expands and contracts.

Follow the manufacturer’s advice for plank alignment and clicking methods.

Use a tapping block and pull bar to keep seams tight without damaging the planks.

Step 4: Lay the First Row

Cut the Short Edge of the First Plank

Start by removing the short tongue edge of your first plank. This helps the plank fit neatly against the wall for a nicer look. Use a utility knife for thin laminates or a circular saw or miter saw for thicker planks.

Place the First Plank 1/4 Inch from the Wall

Put the first plank by your starting wall, leaving a 1/4-inch gap between it and the wall. This gap is important because laminate floors expand and shrink with temperature and humidity.

Use Spacers to Keep the Expansion Gap

Insert spacers between the wall and the floor to maintain the expansion gap as you lay the flooring. Keep using these spacers around the room’s edges.

Stagger End Joints for Strength and Look

For the second row, make the first plank at least 6 inches shorter than the first plank of the last row. This staggers the end joints, making the floor stronger and giving it a natural, random look.

Tip: Don’t line up joints across rows, as it can weaken the floor and make it look unnatural.

Step 5: Cutting Planks to Fit

Straight Cuts — Score and Snap

For straight cuts (like trimming the end of a plank):

Use a utility knife to cut along your marked line.

Break the plank along the line for a smooth cut (best for thin laminates).

For thicker laminate, use a laminate cutter, circular saw, or miter saw for clean cuts.

Irregular Cuts — Around Corners and Obstacles

When cutting around door frames, corners, or tricky shapes:

Use a jigsaw or oscillating multi-tool.

These tools make precise, curved cuts that normal saws can’t do.

Cutting Around Pipes

Measure the diameter of the pipe and add 1 inch for expansion.

Drill a hole in the plank to fit the pipe size.

Cut from the hole to the plank’s edge.

Once installed, seal around the pipe with a bead of silicone caulk to close the gap.

Tight Spaces — Under Door Jambs

Use a jamb saw to trim the bottom of the door frame.

This lets you slide the laminate plank under it neatly.

Pro Tip: Always wear safety goggles and go slowly with power tools to avoid damaging laminate.

| Cutting Task | Recommended Tool(s) | Technique |

|---|---|---|

| Straight cuts (length/width) | Utility knife (thin laminate) Laminate cutter or miter saw (standard) | Score and snap for thin laminate Use a saw for straight cuts |

| Irregular cuts (corners, curves) | Jigsaw or oscillating multi-tool | Mark the shape, cut slowly |

| Around pipes | Drill + Jigsaw or Hole saw | Drill a hole, cut a slit to the edge |

| Tight spaces (door jambs) | Jamb saw | Undercut the jamb |

| Final fitting/trimming | Utility knife or laminate cutter | Trim excess for a snug fit |

Step 6: Laying Subsequent Rows

Angle the Planks into Place

Start each new row by tilting the tongue of the plank into the groove of the last row. Lower it gently until it clicks or fits well.

Use a Tapping Block and Non-Marring Hammer

To make sure it fits tightly, use a tapping block and a non-marring hammer (or mallet).

Put the tapping block against the plank’s edge.

Tap softly to close any gaps between planks.

Never use a standard hammer directly on the laminate—it can chip or harm the edges.

Maintain the Staggered Pattern

Keep staggering the end joints by at least 6 inches in each row for stability and a natural look.

Check Expansion Gaps

Use spacers along the walls to keep the 1/4-inch expansion gap during installation.

Step 7: Finishing the Installation

Install Transition Strips

After laying all planks, put transition strips at doorways and where laminate meets other floors. These strips:

Make a smooth, safe change between floors.

Guard the edges of your laminate.

Follow the maker’s guide for type and setup.

Transitioning to Other Flooring

Pick the right transition type:

T-molding for floors of the same height.

Reducer strips for moving to lower floors like tile or vinyl.

Attach these strips to the subfloor, not the laminate, and leave a 1/4-inch gap to stop buckling.

Reinstall Baseboards

Put baseboards back, attaching them to the wall, not the floor, so the laminate can move underneath.

Allow the Floor to Settle

Before placing furniture back or walking a lot on the floor:

Let it sit for at least 48 hours to get used to the room’s temperature and humidity.

Common Mistakes to Avoid When Installing Laminate Flooring

Installing in High-Moisture Areas

Laminate flooring is not good for very wet areas like bathrooms or laundry rooms. Water can get into the seams and cause swelling or warping.

Using a Hammer Directly on Planks

Do not hit laminate planks with a hammer. Use a tapping block or pull bar to gently secure planks without hurting their edges.

Overlapping End Joints

Do not line up or overlap end joints of planks in nearby rows. This makes the floor weak and can cause gaps or uneven spots. Stagger the joints by at least 6 inches.

Skipping the Expansion Gap

Always leave a 1/4-inch expansion gap around the room’s edge. This prevents buckling when the floor changes with temperature and humidity.

Walking on the Floor Too Soon

Let the laminate floor settle for 48 hours after installation before walking on it or placing heavy furniture.

Tips for a Successful Laminate Flooring Installation

- Measure Accurately and Plan for Waste

Measure your room well and buy 10% more laminate flooring for cuts, mistakes, and repairs. Inspect Planks Before Installation

Look over each plank for flaws or damage before using. Put aside any flawed pieces to keep the finish nice.Use Knee Pads for Comfort

Use knee pads to protect your knees, especially for long work times. This helps you work better.Work Methodically and Don’t Rush

Go slow with each step from starting to cutting planks. Rushing can cause bad fits and mistakes.Maintain the Recommended Expansion Gap

Always leave a 1/4-inch expansion gap around the edges to stop buckling as the laminate changes size.

DIY vs. Professional Laminate Flooring Installation

Many people like laminate flooring because it’s easy to install yourself. Deciding to do it yourself or hire someone depends on how comfortable you are, what tools you have, and how complicated the project is.

DIY Installation

✅ Pros:

Save money on labor costs ($2 to $5 per sq ft).

Work at your own speed.

Good for small, simple rooms.

❌ Cons:

Need basic tools (spacers, block, saws).

Mistakes like wrong gaps can cause issues.

Takes a lot of time, especially for big or odd spaces.

Professional Installation

✅ Pros:

Quick and exact installation.

Experts handle tricky parts and prep work.

Often comes with a warranty.

❌ Cons:

Costs more — adds $2 to $5 per sq ft for labor.

Usually, laminate flooring installation (materials + labor) costs between $4 and $12 per square foot based on style and difficulty. For more details, see our Laminate Flooring Cost Guide.

| Installation Method | Average Cost per Sq Ft | Pros | Cons |

|---|---|---|---|

| DIY Installation | $1.50 – $4 (materials only) | Save on labor Flexible schedule Good for small areas | Time-consuming Requires tools & skills Mistakes can be costly |

| Professional Installation | $4 – $12 (materials + labor) | Fast & precise Warranty often included Handles complex cuts & transitions | Higher upfront cost |

Do You Need Professional Help With Your Laminate Flooring Installation Project?

Now you know how to install laminate flooring, you’re ready to make a stylish, strong floor. If you want to skip the hard work, our expert team can help.

We do it all — from getting the subfloor ready to aligning the planks perfectly — so you can relax and enjoy great results. We’ll help you pick the right laminate style and underlayment for your space and budget.

Contact us today to schedule your free in-home consultation and see if we serve your area.